What is a Good Electrical Connection?

A good electrical connection is one that is able to conduct current safely at a low temperature, resulting in energy saving. It should also be able to last for many years, up to 30 years or even longer.

A bad electrical connection on the other hand conducts current poorly at higher temperature, creating heat loss and even risk of fire. For a building that consists of many joints and terminations, every connection’s heat loss adds up. Even if each connection were to lose a few Watts, the lost multiples by many numbers of connections, over a period of 24 hours for 365 days in a year will equate to a big heat loss and wastage.

Danger of a Bad Electrical Connection

In a bad electrical connection, the temperature of the connection will rise and get higher than the temperature of the conductor. The severity of the temperature rise will depend on the load the conductor is carrying. This temperature rise will result to heat loss and energy waste.

If this situation persists, the excessive temperature will start to melt the cable insulation and burn its surrounding contact. This bad electrical connection now becomes a fire risk and the end result can be tragic.

Termination Failure

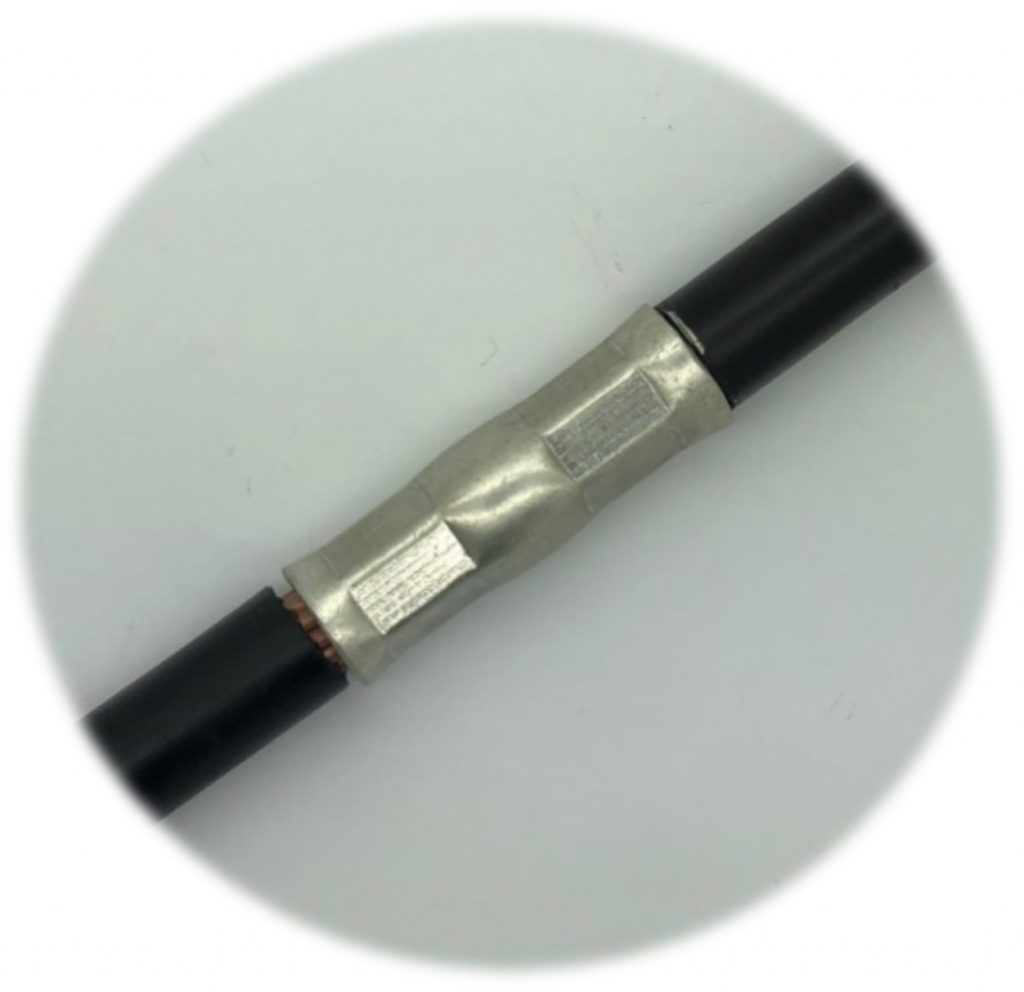

Joint Failure

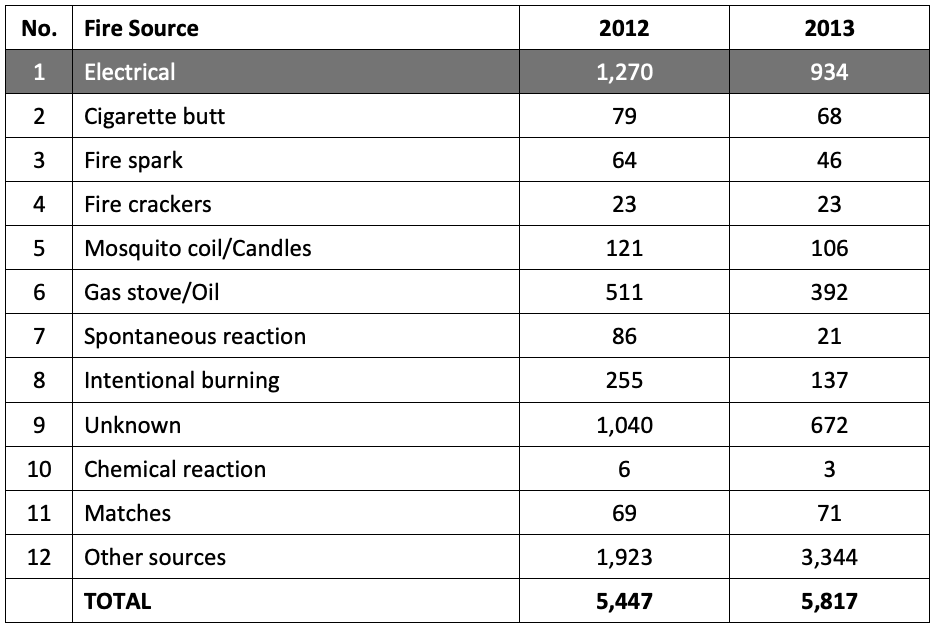

The Fire Investigation Department of BOMBA Malaysia reported for year 2013, a total 934 cases of fire is caused by electrical faults in buildings. This represents approximately 16% of the total cases (5,817) recorded in year 2013 for the whole of Malaysia.

The statistic is was more alarming for year 2013, where a total of 1,270 cases of fire were found to be caused by electrical faults in buildings. This constitutes about 23% of the total fire cases recorded (5,447) in building for the whole of Malaysia.

There were no specifics on the electrical fire source provided the department, but we suspect that a large number of the fire incidents under the electrical fire source can be attributed to electrical joint and termination faults.

The table below summarizes the statistics obtained from The Fire Investigation Department of BOMBA Malaysia:

A Good Connection starts with the Right Connector

There are generally three important factors in executing a good electrical connection: 1- Type of Connectors, 2 – Crimping Tools and Dies, and 3 – Workmanship.

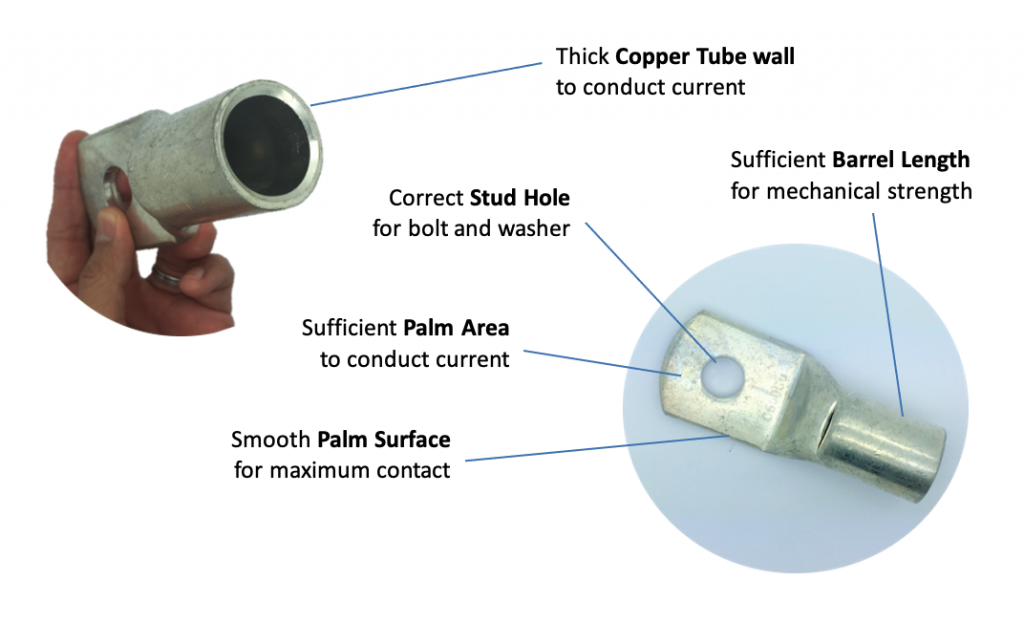

A good electrical joint or termination starts with using the right type of connector. Copper cable lugs are used to terminal Copper cables and cable links are used to join Copper cables. The material and dimensions of these connectors are important consideration in contributing to a good electrical connection.

Cable Termination

Cable Joint

Good connectors must be made of Copper that comes in a high conductivity copper tube with suitable thickness. A cable lug must have sufficient palm area and barrel length, whilst a link should have sufficient link length, both plated with Tin to prevent corrosion. Copper has many grades. For electrical purposes, the Electrolytic Copper (E.Cu) with purity 99.9% and conductivity 99% I.A.C.S. is always used. Using low quality recycle copper is not recommended, as the conductivity is only 50% to 85%.

Characteristics of a Good Cable Lug

Malaysian Standards for Cable Connectors

In Malaysia, various types of cable lug and link are imported into the country. Some of these imported cable lugs and links have been found to inferior as they differ in the required dimensions and are made from inferior materials.

In order to prevent the widespread usage of these inferior connectors, the Department of Standards Malaysia has developed and published a serious of Malaysian Standards to standardize the quality of cable connectors.

MS 1540:2015

Crimp type Cable Lugs for use with Copper conductors in LV applications

MS 1779:2005

Crimp type Cable Links for use with Copper conductors in LV applications

MS 1838:2005

Heavy duty crimp type Cable Lugs for use Copper conductors in applications up to 36 kV

With the Malaysian Standards, it would be easier for owners, engineers, contractors and end-users to specify the right cable connectors for their requirements.

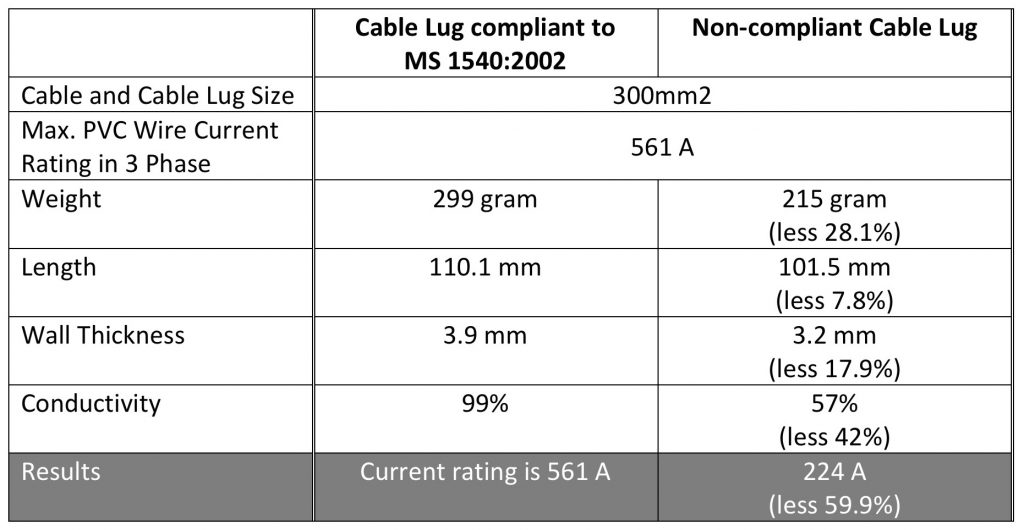

Cable connectors that do not meet the Malaysian Standard as minimum requirements can cause negative repercussion to the electrical connection. To demonstrate this we compared a Malaysian Standard compliant cable lug against one that is available in the market (non-compliant cable lug). The cable lugs were measured in terms of dimensions and conductivity. The non-compliant cable lug was found to be inferior in terms weight, length, wall thickness and conductivity. The end result is that the performance capacity of the non-compliant lug is badly affected.

What this means is that the non-compliant cable lug is not able to carry the current load which it is expected to. In this case, a 300mm2 Malaysian Standard compliant cable lug has a maximum current rating of 561A. The non-compliant cable lug can only perform up to a maximum of 224A only, or approximately 60% less than the standard-compliant counterpart.

Comparison between a Compliant and Non-compliant 300mm2 Cable Lug

This experiment may be simple, but it clearly demonstrates the danger of using inferior and non-standard-compliant cable lugs in any projects. An inferior connector will not be able to shoulder the current load the circuit has been designed for.

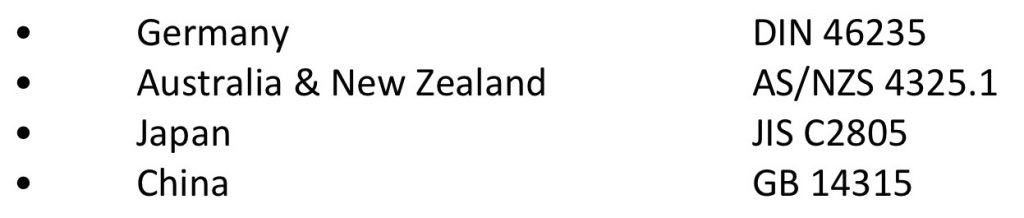

The development of the Malaysian Standards for connectors is certainly a step in the right direction. This is because there are actually no standardized International Standards for the dimension and material of connectors. However, developed countries listed below have adopted their own national standards to control and regulate the Copper connectors used in their respective countries.

All these countries also adopt IEC 61238 for the testing methods and requirements for compression and mechanical Connectors.

Crimping Tools and Dies

Another equally important factor to achieving a good electrical connection is using the correct crimping tools and matching dies. A proper tool and die are necessary to perform a good connection. Many imported connectors, good quality or sub-standard type, cannot find matching dies in Malaysia. This is because the importers of these connectors do not import the matching dies for the connectors.

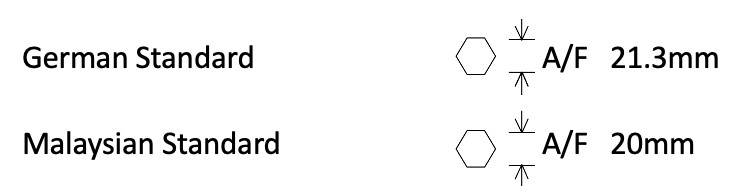

In an example of a 185mm2 cable lug, there is a difference between German DIN Standard and Malaysian Standard in the Across Flat (A/F) dimension. As a result, using the DIN Standard die on a Malaysian Standard cable lug will result in under crimping.

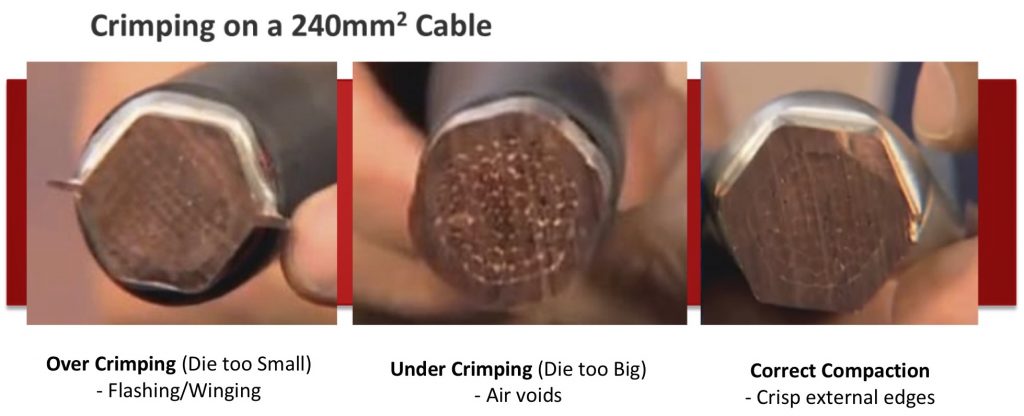

Using a non-matching die will result in over-crimping or under-crimping as illustrated in the diagrams below. Therefore a customised die suitable for Malaysian connectors is required.

The correct die sizes must always be used and the specifications are now available in the new Malaysian Standards for hexagon and rounding dies.

MS 2654:2015

Crimping type Hexagon Dies for Cable Lugs, Cable Links and the Rounding Dies for Sector Cable – Installation method and specification for the materials, marking and dimensions

The Human Factor

Malaysian Standards on connectors are meant to standardise and to prevent the use of inferior and unsuitable cable lugs in the connection of conductors to electrical equipment. The guideline for the overall cable lug dimensions was drafted with due consideration to the current practices that exist in the industry and the common usage of crimping tools and dies. Therefore, in order to avoid unnecessary problems, the Malaysian Standard should be specified during the purchase cable lugs or cable links. Engineers and planners have the responsibility to specify cable lugs or links that comply with the Malaysian Standards. Users too, should insist on buying the right cable lugs and links so that the connection will be at an optimum temperature to avoid dangerous applications, and thus help ensure electrical installations are safe.

The use of non-matching die for cable lugs, cable links, and sector copper conductor in electrical installations can be prevented if users are aware of the right tools being used for our standard Malaysian connectors. The last factor but not least is on workmanship, where the right procedure of crimping must be followed to ensure the standard compliance cable connectors and crimping tools would result in achieving good if not excellent electrical connections.